Manufacturing Method

We make high quality products

with thorough quality control and unique technology

with thorough quality control and unique technology

From molding to drying, sorting, and packaging.

We introduce each process from product manufacturing to shipping.

We introduce each process from product manufacturing to shipping.

01

Molding Process

Carefully selected ingredients are formed with skillful techniques. Seasonings and other ingredients are added to fish paste to create a paste of meat, which is then passed through a forming machine. After the process, the meat is cut into specified lengths and heated as necessary. Then, the heated fish paste is cooled and frozen in a freezer.

①Defrosting

②Mixing

③Forming

④Heating

⑤Alignment

Air Drying

Freeze Drying

Microwave Drying

02

Drying Process

Frozen kamaboko are cut into thin tips and dried. The products are placed in an air-drying machine and dried with hot air. Because the material is made to float and flow, there are almost no unevenness, adhesion, or loss of shape. After drying, the materials are passed through a specific gravity sorter to remove defective cuttings and stored as semi-finished products.

①Defrosting

②Cutting

③Flow-through primary drying

④Rotary secondary drying

⑤Wind sorting

⑥Tentative packing

02

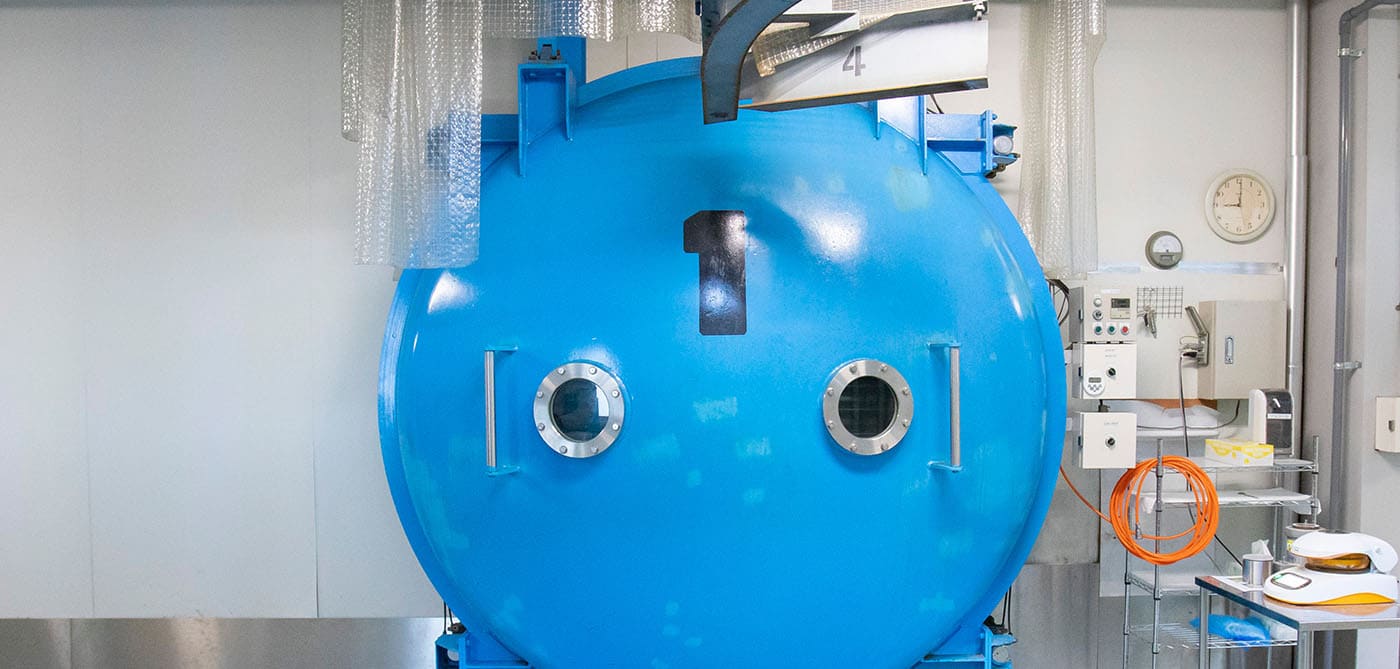

Drying Process

Frozen kamabokos are cut into thin slices and dried. The products are placed in a freeze-drying machine and vacuum freeze-dried. Compared to hot-air drying, freeze-drying is characterized by less loss of aroma and nutrients because the frozen materials are sublimate dried under vacuum and low temperature. After drying, the material is passed through a specific gravity sorting machine to remove defective cuttings, and then stored as semi-finished products.

①Defrosting

②Preparing

③Pre-freezing

④Vacuum freeze drying

⑤Taking out from the oven

(humidity control for some products)

(humidity control for some products)

⑥Tentative packing

02

Drying Process

Frozen fish cakes are cut into thin slices and placed in a microwave heating machine for drying. Microwaves are transmitted to the center of the food and rapidly heat up and evaporate, leaving gaps where water used to be inside the food, resulting in a product with a light texture and good restorability. After drying, the materials are passed through a specific gravity sorting machine to remove defective cuttings, and then stored as semi-finished products.

①Molding

②Roasting

③Microwave drying

④Cutting

⑤Cooling

⑥Tentative packing

03

Selection Process

Defective products are removed from semi-finished products by visual sorting and then transferred to machine sorting. The machine carefully checks for cracks, chips, small foreign objects that cannot be visually removed, and removes them.

①Visual sorting

②Vibration sieving

③Metal detector

④X-ray check

⑤Color sorter

⑥Sorting on conveyor belt

04

Packing Process

After filling the internal bag with Kamaboko and weighing, the top of the bag is sealed with a heat seal. Finally, the products are packaged for storage and shipped to the customer according to the order.

①Interior packaging

②Outer box packaging

③Shipping